|

Double lip

seals retain oil while locking out dirt |

|

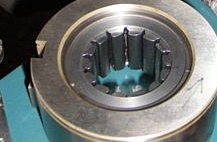

Helical

gear tooth design maximizes the power transfer efficiency |

|

Twin taper

bushings eliminate play between the reducer and shaft. No set

screws to score, mark or gouge the shaft |

|

Reducer

mounts directly on driven shaft, eliminating the need for

coupling or chain drive, sliding motor base and support

structure and avoiding all alignment problems |

|

Easy

Installation: Insert shaft key and slide inboard bushing,

reducer and outboard bushing onto the device's input shaft.

Position and tighten bushing mounting screws. |

|

Easy

Removal: Bushing screws double as jacking screws so no puller is

required. Remove the bushing mounting screws and insert them

into the tapped holes in the bushing flanges. Once tightened,

the reducer should slide easily off of the shaft. |

|

Flexibility: Mounting versatility enables these torque arm

reducers to be positioned anywhere along the driven shaft in

horizontal, vertical and inclined positions for greater

installation ease. |

|

Heavy Duty

Cast Housing: The corrosion resistant, ductile iron cast

housings are precision machined. A ribbed housing construction

provides strong, rigid support for bearings and gearing. This

design also channels oil to all bearings for superior

lubrication and extended operating life. |

|

Benefits |

|

One-year

warranty |

|

Continuing

service commitment |

|

Global

distribution |

|

Rapid

delivery |

|

Off-the-shelf parts |

|

Superior

quality |

|

Advanced

materials & processes |

|

Improved

service life of critical components |

|

Lower

maintenance & operating costs |

|

|